Milled lactose

MEGGLE has it.

The right milled lactose product for wet and dry granulation

In traditional, pharmaceutical dry and wet granulation operation finer particles have proven to be beneficial.

Milled α-lactose monohydrate is available in fine particle size (PS) with narrow particle size distribution (PSD), defined surface properties and density ranges. This allows to modulate in particular a solid formulation’s compactibility, compressibility, porosity, and segregation tendency. Brittle α-lactose monohydrate exhibits good binding properties, and consolidates mainly by fragmentation, but particle flow of milled lactose grades is moderate, depending on size and its corresponding specific surface

Milled lactose grades: A perfect product platform

However, for many important pharmaceutical agglomeration processes (e.g. in economical direct compression) both compactibility and flowability are primordial. Milled lactose grades represent a perfect product platform, for they can be modified greatly, fulfilling the needs of various applications. Impacting particle characteristics by agglomeration has been an early undertaking, where flowability was optimized by a simple and gentle particle size enlargement step, leading into the product family of agglomerated Tablettose®. Dispersion of a milled lactose suspension through a nozzle allows to optimize particle porosity, shape and surface in one step, resulting into the product group of spray-dried lactose (FlowLac® 90/100).

Variety of PSD: Flexibility in tableting

Milled lactose grades also have a long tradition in dry granulation procedures using roller compaction or slugging. These processes consist of a primary agglomeration and a final milling step. In roller compaction due to force feeding reduced powder flow is of minor importance, in some cases low segregation tendency of milled lactose grades may be even seen advantageous for content uniformity reasons. In well-established slugging processes flat compacts are manufactured preferentially avoiding die filling issues. MEGGLE offers a variety of PS/PSD of milled lactose grades offering flexibility in tableting during the second compaction step.

Extrusion/spheronization processes also make use of milled lactose as a filler.

After all, disaccharide lactose may be metabolized by bacteria or fungi and is mainly used in its milled form as bulk substrate/medium for fermentation in bio-industries.

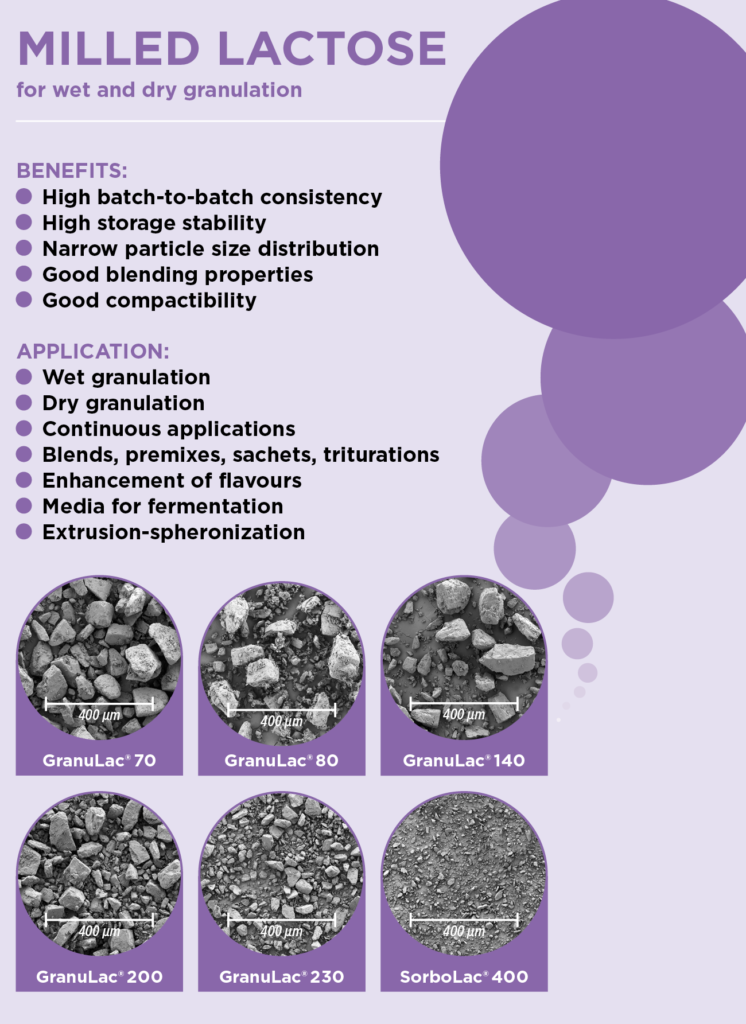

MEGGLE’s milled lactose grades suitable for wet and dry granulation are available under the trade names

GranuLac® 70, GranuLac® 80, GranuLac® 140, GranuLac® 200, GranuLac® 230 and SorboLac®400

MEGGLE has it.

The right milled lactose product for wet and dry granulation

In traditional, pharmaceutical dry and wet granulation operation finer particles have proven to be beneficial.

Milled α-lactose monohydrate is available in fine particle size (PS) with narrow particle size distribution (PSD), defined surface properties and density ranges. This allows to modulate in particular a solid formulation’s compactibility, compressibility, porosity, and segregation tendency. Brittle α-lactose monohydrate exhibits good binding properties, and consolidates mainly by fragmentation, but particle flow of milled lactose grades is moderate, depending on size and its corresponding specific surface

Milled lactose grades: A perfect product platform

However, for many important pharmaceutical agglomeration processes (e.g. in economical direct compression) both compactibility and flowability are primordial. Milled lactose grades represent a perfect product platform, for they can be modified greatly, fulfilling the needs of various applications. Impacting particle characteristics by agglomeration has been an early undertaking, where flowability was optimized by a simple and gentle particle size enlargement step, leading into the product family of agglomerated Tablettose®. Dispersion of a milled lactose suspension through a nozzle allows to optimize particle porosity, shape and surface in one step, resulting into the product group of spray-dried lactose (FlowLac® 90/100).

Variety of PSD: Flexibility in tableting

Milled lactose grades also have a long tradition in dry granulation procedures using roller compaction or slugging. These processes consist of a primary agglomeration and a final milling step. In roller compaction due to force feeding reduced powder flow is of minor importance, in some cases low segregation tendency of milled lactose grades may be even seen advantageous for content uniformity reasons. In well-established slugging processes flat compacts are manufactured preferentially avoiding die filling issues. MEGGLE offers a variety of PS/PSD of milled lactose grades offering flexibility in tableting during the second compaction step.

Extrusion/spheronization processes also make use of milled lactose as a filler.

After all, disaccharide lactose may be metabolized by bacteria or fungi and is mainly used in its milled form as bulk substrate/medium for fermentation in bio-industries.

MEGGLE’s milled lactose grades suitable for wet and dry granulation are available under the trade names

GranuLac® 70, GranuLac® 80, GranuLac® 140, GranuLac® 200, GranuLac® 230 and SorboLac®400