Micronized lactose for dry powder inhalation

MEGGLE has it.

The right micronized lactose for dry powder inhalation

The delivery of active pharmaceutical ingredients (APIs) via the lung is becoming increasingly important as more and more patients all over the world suffer from chronic respiratory diseases.

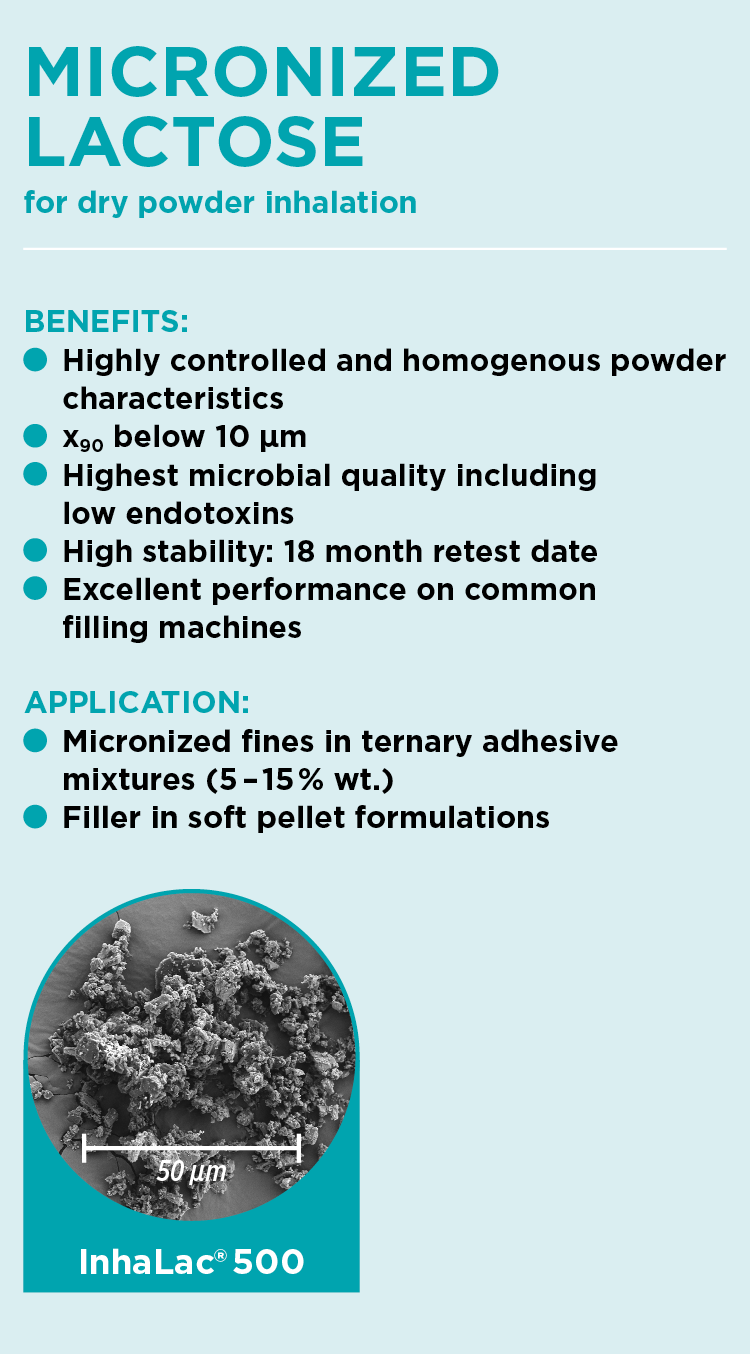

InhaLac® 500: Fine tune your DPI formulation

Besides the carrier lactose and the active pharmaceutical ingredient, many dry powder inhalation formulations contain additionally fine milled or micronized lactose.

The addition of lactose fines (< 15 µm) in ternary powder mixtures for inhalation is well-known to increase the fine particle fraction (FPF, < 5 µm).

Numerous scientific publications have shown that the addition of micronized lactose to coarser lactose, which acts as carrier for the API in DPIs, can drastically improve the DPI’s performance by increasing its fine particle fraction. One mechanism, which is discussed for the performance improvement is called high energy site theory, where the fine milled/micronized lactose covers the so-called high energy sites of the coarser lactose, preventing the API from strong attachment to its carrier.

With InhaLac® 500, MEGGLE completes its portfolio with a true micronized grad with a x90 below 10 µm.

Micronizing of lactose requires advanced processing skills due to inherent difficulties, which arise when exceptional high energy input through milling is required, to overcome strong crystal lattice bonding forces.

Size reduction also leads to significant increase of the material’s specific surface area, resulting in agglomeration and lumping of the freshly micronized material. Therefore, the micronization itself and the related downstream operations such as material handling, filling, packaging, and storing account for micronized products’ special position among the milled lactose grades. Micronized lactose has gained massive popularity among dry powder inhaler (DPI) developers, trying to push the fine particle fraction (FPF, amount of API which is actually delivered to the deep lung) to the maximum.

The resulting improvement of the FPF has its natural limitation as the addition of fine milled or mircronized material deteriorates the powder blend’s overall flowability, which can limit its processability, filling powder into capsules. As mentioned above, milling to that extend leads to relevant specific surface enlargement, which allows for possible interaction between the powder and its environment in particular humidity, found in the surrounding air. Therefore, throughout production, packaging, and transportation of micronized lactose, MEGGLE has made sure to carefully select and – if necessary – to optimize process steps as well as process conditions in order to deliver this susceptible product, having the highest quality possible.

Batch-to-batch consistency for all lactose products is due to MEGGLE’s technical expertise in lactose manufacture. Our stringent release criteria and constant process control ensure our products’ consistency and quality.

MEGGLE’s InhaLac® grades comply with the current harmonized USP-NF, Ph. Eur. and JP monographs. In order to meet the special requirements for pulmonary drug delivery, additional and in some cases even stricter specification limits are in place for all InhaLac® grades. These exceed even those currently required by the pharmacopoeias.

MEGGLE´s micronized lactose grade for DPI is available under the trade name InhaLac® 500

Information / Sample request:

MEGGLE has it.

The right micronized lactose for dry powder inhalation

The delivery of active pharmaceutical ingredients (APIs) via the lung is becoming increasingly important as more and more patients all over the world suffer from chronic respiratory diseases.

InhaLac® 500: Fine tune your DPI formulation

Besides the carrier lactose and the active pharmaceutical ingredient, many dry powder inhalation formulations contain additionally fine milled or micronized lactose.

The addition of lactose fines (< 15 µm) in ternary powder mixtures for inhalation is well-known to increase the fine particle fraction (FPF, < 5 µm).

Numerous scientific publications have shown that the addition of micronized lactose to coarser lactose, which acts as carrier for the API in DPIs, can drastically improve the DPI’s performance by increasing its fine particle fraction. One mechanism, which is discussed for the performance improvement is called high energy site theory, where the fine milled/micronized lactose covers the so-called high energy sites of the coarser lactose, preventing the API from strong attachment to its carrier.

With InhaLac® 500, MEGGLE completes its portfolio with a true micronized grad with a x90 below 10 µm.

Micronizing of lactose requires advanced processing skills due to inherent difficulties, which arise when exceptional high energy input through milling is required, to overcome strong crystal lattice bonding forces.

Size reduction also leads to significant increase of the material’s specific surface area, resulting in agglomeration and lumping of the freshly micronized material. Therefore, the micronization itself and the related downstream operations such as material handling, filling, packaging, and storing account for micronized products’ special position among the milled lactose grades. Micronized lactose has gained massive popularity among dry powder inhaler (DPI) developers, trying to push the fine particle fraction (FPF, amount of API which is actually delivered to the deep lung) to the maximum.

The resulting improvement of the FPF has its natural limitation as the addition of fine milled or mircronized material deteriorates the powder blend’s overall flowability, which can limit its processability, filling powder into capsules. As mentioned above, milling to that extend leads to relevant specific surface enlargement, which allows for possible interaction between the powder and its environment in particular humidity, found in the surrounding air. Therefore, throughout production, packaging, and transportation of micronized lactose, MEGGLE has made sure to carefully select and – if necessary – to optimize process steps as well as process conditions in order to deliver this susceptible product, having the highest quality possible.

Batch-to-batch consistency for all lactose products is due to MEGGLE’s technical expertise in lactose manufacture. Our stringent release criteria and constant process control ensure our products’ consistency and quality.

MEGGLE’s InhaLac® grades comply with the current harmonized USP-NF, Ph. Eur. and JP monographs. In order to meet the special requirements for pulmonary drug delivery, additional and in some cases even stricter specification limits are in place for all InhaLac® grades. These exceed even those currently required by the pharmacopoeias.

MEGGLE´s micronized lactose grade for DPI is available under the trade name InhaLac® 500