Agglomerated lactose

MEGGLE has it.

The right agglomerated lactose product for direct compression

MEGGLE invented in the 70´s the well-known and popular product family Tablettose® – A robust agglomeration technique translates into a robust excipient, which is essential to robust drug manufacturing.

Tablettose® is produced in a continuous manufacturing, a concept which is still quite new for the pharmaceutical industry, but very well accepted and understood by the food industry.

Continuous manufacturing: Reduced production cost

MEGGLE’s deeply rooted expertise in food production and willingness to conquer the pharmaceutical industry helped a lot to apply the concept of continuous manufacturing to the production of pharmaceutical grade excipients. Not only can MEGGLE take advantage of reduced production cost through continuous manufacturing, which allows for very competitive pricing, a consistent product quality and performance can be achieved through continuous manufacturing.

Agglomerated lactose: Excellent flowability and compactibility

The beauty of agglomerated lactose is its given functionality (excellent flowability and compactibility), while its regulatory status is “save”. Tablettose® complies with all compendial requirements worldwide, which are set for lactose monohydrate. This means, whenever lactose monohydrate is considered as part of a pharmaceutical drug formulation, the drug developer has a highly functional excipient on hand, which’s regulatory status is crystal clear and accepted by the authorities.

Tablettose®: For moisture-sensitive API formulations

Although MEGGLE uses a fair amount of water for lactose’s agglomeration, the final product provides a remarkable low amount of potentially active surface water (< 0.5 %), which allows for the use of Tablettose® in formulations, which containing moisture-sensitive active pharmaceutical ingredients (API). As lactose monohydrate is non-hygroscopic by any means, stability issues, due to water uptake, should not be of any concern.

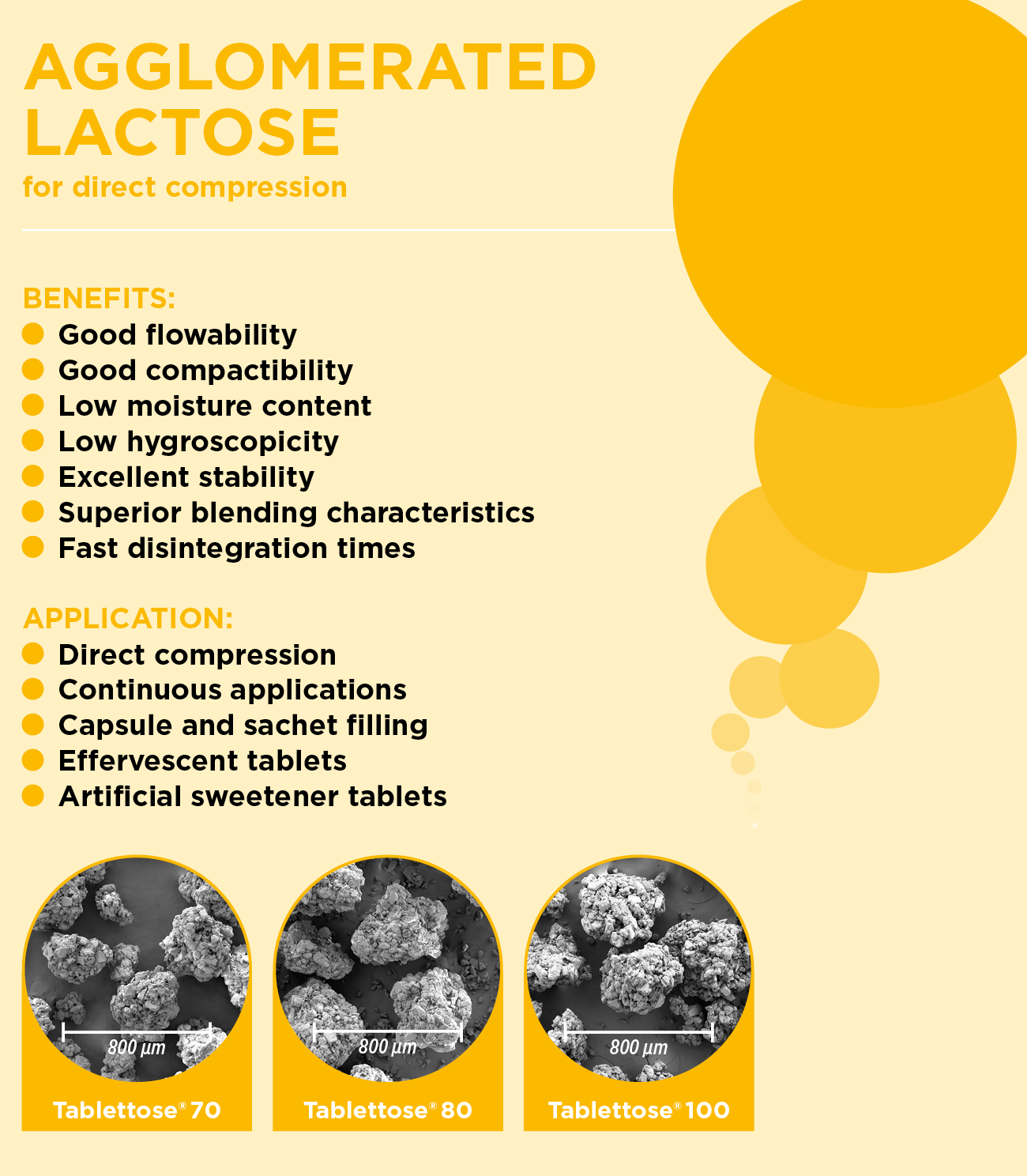

Tablettose®: 3 products – different advantages

The Tablettose® family comprises 3 members to date, each one having its distinct advantages. Tablettose® 80 covers the broadest range of drug formulations and is therefore the first go-to choice when it comes to cost effect and reliable direct compression. Next to Tablettose® 80 developers can choose Tablettose® 70. In case of serious flowability issues caused by a very fine API(s) or other formulation ingredients, which impair sufficient powder flow into the tablet press’s die. Fines in particular can create issues throughout the whole compaction process. Therefore, Tablettose® 70’s minimized content of particles smaller than 63 µm (NMT 6 % < 63 µm). This guarantees reliable tableting results. It´s important to know that a low fines content allows for higher throughput as dust is virtually not present, which minimizes the need of frequent cleaning. Tablettose® 100 on the other hand is an ideal choice if an increased drug load and a high compactibility is required.

MEGGLE’s agglomerated lactose grades suitable for direct compression are available under the trade names

Information / Sample request:

MEGGLE has it.

The right agglomerated lactose product for direct compression

MEGGLE invented in the 70´s the well-known and popular product family Tablettose® – A robust agglomeration technique translates into a robust excipient, which is essential to robust drug manufacturing.

Tablettose® is produced in a continuous manufacturing, a concept which is still quite new for the pharmaceutical industry, but very well accepted and understood by the food industry.

Continuous manufacturing: Reduced production cost

MEGGLE’s deeply rooted expertise in food production and willingness to conquer the pharmaceutical industry helped a lot to apply the concept of continuous manufacturing to the production of pharmaceutical grade excipients. Not only can MEGGLE take advantage of reduced production cost through continuous manufacturing, which allows for very competitive pricing, a consistent product quality and performance can be achieved through continuous manufacturing.

Agglomerated lactose: Excellent flowability and compactibility

The beauty of agglomerated lactose is its given functionality (excellent flowability and compactibility), while its regulatory status is “save”. Tablettose® complies with all compendial requirements worldwide, which are set for lactose monohydrate. This means, whenever lactose monohydrate is considered as part of a pharmaceutical drug formulation, the drug developer has a highly functional excipient on hand, which’s regulatory status is crystal clear and accepted by the authorities.

Tablettose®: For moisture-sensitive API formulations

Although MEGGLE uses a fair amount of water for lactose’s agglomeration, the final product provides a remarkable low amount of potentially active surface water (< 0.5 %), which allows for the use of Tablettose® in formulations, which containing moisture-sensitive active pharmaceutical ingredients (API). As lactose monohydrate is non-hygroscopic by any means, stability issues, due to water uptake, should not be of any concern.

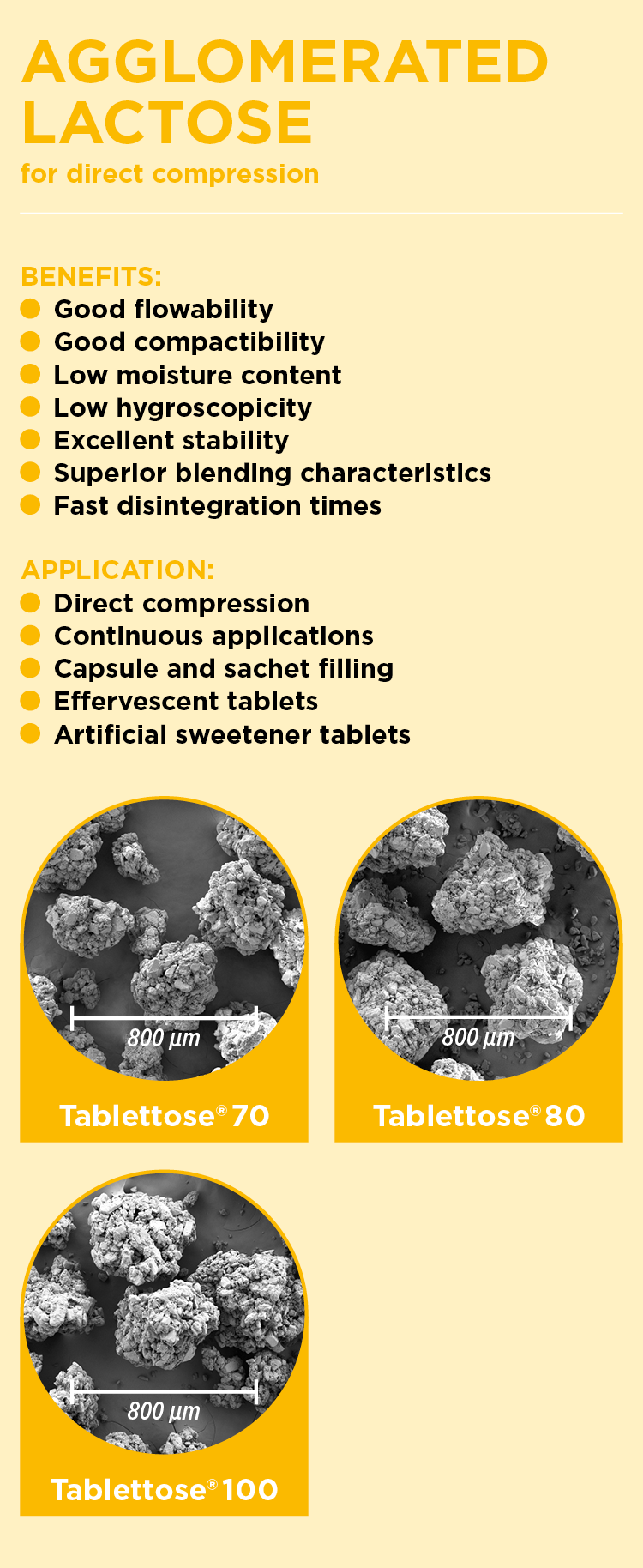

Tablettose®: 3 products – different advantages

The Tablettose® family comprises 3 members to date, each one having its distinct advantages. Tablettose® 80 covers the broadest range of drug formulations and is therefore the first go-to choice when it comes to cost effect and reliable direct compression. Next to Tablettose® 80 developers can choose Tablettose® 70. In case of serious flowability issues caused by a very fine API(s) or other formulation ingredients, which impair sufficient powder flow into the tablet press’s die. Fines in particular can create issues throughout the whole compaction process. Therefore, Tablettose® 70’s minimized content of particles smaller than 63 µm (NMT 6 % < 63 µm). This guarantees reliable tableting results. It´s important to know that a low fines content allows for higher throughput as dust is virtually not present, which minimizes the need of frequent cleaning. Tablettose® 100 on the other hand is an ideal choice if an increased drug load and a high compactibility is required.

MEGGLE’s agglomerated lactose grades suitable for direct compression are available under the trade names